“This

fabric can be used in various industries, such as automobiles and medicine. It

is a major first step toward a manufacturing process that does not depend on

petroleum”

Excerpt from an

interview with Spiber President Kazuhide Sekiyama by The Asahi Shimbun

newspaper on May 25th 2013

Despite

what you’ve heard Spider Silk, which has a tensile strength of 1GPa (Giga

Pascal) is not stronger than Steel, which on average has a tensile strength of

0.5 to 2GPa, depending on the composition of the alloys used to make the Steel.

Rather it’s has the same tensile strengths but with lower density as noted in

the article “Spider

Silk is a wonder of nature, but it's not stronger than steel”, published

Jun 07, 2013 by Michelle Oyen, Phys.org.

So

please dispel that myth; it just ain’t so!

But

Spider Silk, a protein like Hair is truly special. This is thanks in part to

Nature’s efficiency in making materials at the nanoscopic level from Hydrogen,

Oxygen and Carbon instead of using vast amounts of energy as we humans do to

forge such materials as steel to which Spider Silk is often compared. So the

quest to make Spider Silk commercially continues as noted in “Tangled webs: Why scientists

want to recreate Spider Silk”, published 20 March 2013 Last updated at

11:21 By Christopher Brooks, BBC Scotland.

Many

have tried and failed at producing Spider Silk from Spiders, who are mainly

territorial creatures who fight against each other and cannot be made to

produce Silk on demand like domesticated sheep produce wool. Spiders spin their

silk from a protein called fibroin. The protein emerges from their abdomen via

a spinning wart and dries on contact with air to form a fibre that crystalline

yet flexible, waterproof. Spider Silk has found few applications already such

as crosshairs in Gun sights as well as use in Dressings splints for cuts and

fishing lines.

It

main properties, that being lower density and high strength makes it attractive

for making things such as high performance clothing to bullet proof vests

lighter and stronger than Kevlar as noted in Popular Mechanic’s 6

Spider-Silk Superpowers Slideshow!

But

recently a few brave researchers have been quietly succeeding thanks to the use

of a new tool: Genetic Engineering. Their ideas are cleverly simple; instead of

using man-made macroscopic methods of making this elusive material, they

genetically modify other organisms to produce the Spider Silk on demand and in

commercially viable quantities.

The

first such successful attempts were done by USTAR (Utah Science Technology and

Research Initiative) Professor Randy Lewis of Utah State University back in August 2012 as

stated in the article “USTAR

Researcher Randy Lewis Developing Ancient Biomaterial for the Future”,

published Thursday, Aug. 30, 2012, Utah State

University News. Professor Randy Lewis was using the following to create

artificial Spider Silk:

1. Transgenic

Goats

2. Transgenic

Escherichia Coli Bacteria

3. Transgenic

Alfalfa

4. Transgenic

Silk Worms

The

Transgenic Goats produced Spider Silk Proteins but assembling them into Spider Silk

with the same tensile strength proved difficult.

However,

more recently in February 2013, USTAR Research Professor Randy Lewis, who has

been working on developing methods of manufacturing Spider Silk for the past

three decades and holds a eight (8) patents relating to Transgenic methods used

to produce Spider Silk proteins and Araknitek Artificial Spider Silk for

commercial usage as described in Spinning

a Stronger Future: Arakniteck Creates Synthetic Spider Silk, viewed July

1st 2013, USTAR, has persevered.

He’s

published a series of books describing his misadventures with the transgenic

critters, which kiddies obviously love as much as Charlotte’s web as noted in “USU's Spider Silk

Research Spawns a Web of Literary Offerings”, published Thursday, Feb. 28,

2013, Utah State University News.

More

recently in January 2013, USTAR Professor Randy Lewis in collaboration with Dr.

Malcolm Fraser from the University of Notre Dame has succeeded with Transgenic Silkworms

and has created a synthetic blend of Spider Silk and Silkworm Silk as reported

in “Genetically

Engineered Silkworms Spin Like Spiders”, published February 11, 2013 03:00

AM ET, Discovery News.

While

not as strong as Spider Silk, it bests SilkWorm Silk and is thus commercially

viable as it uses the same machinery of Silkworms to make Spider-SilkWorm Silk!

It still holds the potential to become genuine Spider Silk by the introduction

of even stronger Spider Silk Genes from the Darwin's Bark Spider (Caerostris

darwini).

More

recently, however, some Spider silk Researchers at a Japanese startup Spiber

have succeeded in using Transgenic Bacteria to make spider silk which they call

Qmonos (from kumonosu or “spider web” in Japanese) as stated in the

article “Dress

to kill in this synthetic spider silk outfit”, published May 26, 2013 12:55

PM PDT by Tim Hornyak, CNET News and “Ready

to web: The ultra strong dress made from synthetic SPIDER SILK” published

27 May 2013 UPDATED: 16:28 GMT, 27 May 2013 By Rachel Reilly, Mail Online.

Dr.

My Hedhammar of the Swedish University of Agricultural Sciences and Director of

R&D at Spiber Technologies in Uppsala are behind the success on this

frontier of Spider Silk Research using Transgenic Escherichia

Coli Bacteria. In patent No. 8,278,416 as described in the article “Patent

Watch: Man-Made Spider Silk”, published June 1, 2013 By Marissa Fessenden, Scientific American they detail:

1. Two

(2) modified spider silk proteins

2. Describe

how they can be coaxed to self-assemble

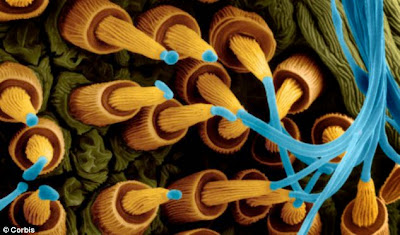

Clearly

the picture Electric Blue Cocktail Dress below it proves that the technology of

Spiber not only works. A victory for all fashionistas but also for business

interest looking to commercialize Spider Silk Production!

This

is now the case with Spider, which has contracted Kojima Industries to build a

plant to crank out 220 pounds of the synthetic silk a month and 10 tons of

spider silk a year by 2015 as reported in

the Japanese Newspaper, The Asahi Shimbun in the article “Company

develops technology to mass-produce 'spider silk' fabric”, published May

25, 2013 By TARO MIZOGUCHI/ Staff Writer, The

Asahi Shimbun.

Two

Scientific ventures, one American and One Japanese have succeeded where other

have failed. USTAR Research Professor Randy Lewis has succeeded in making

synthetic Spider-Silkworm Silk from Transgenic Silkworms, which already may be

commercially viable and now Spiber has succeeded in developing Qmonos Spider

silk from Transgenic Escherichia Coli

Bacteria.

Spider

Silk is the next big trend in Fabrics which means I’m Out Ciara and Nikki Minaj

Style!

No comments:

Post a Comment